Time:2024-05-11

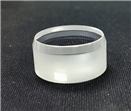

Sapphire is a type of corundum that is widely used in industry due to its high temperature resistance and corrosion resistance. The Mohs hardness is 9, making it a hard material that can resist most scratches and wear. Vickers hardness testing is a method used to measure the hardness of materials, typically in the range of 2000 to 2200 megapascals (MPa), which further confirms their hardness. Due to its high hardness and relatively complex processing, the following are some of the main methods for processing sapphire lenses:

1. Cutting: Sapphire can be cut with diamond cutting tools, which themselves need to be hard to withstand the hardness of sapphire.

2. Grinding: Grinding is a common method of shaping sapphire into the desired shape, which requires the use of diamond grinding wheels for grinding. This process usually requires high precision to ensure high-quality sapphire products.

3. Polishing: Polishing is a key step in improving the surface smoothness and transparency of sapphire lenses, typically involving the use of special grinding and polishing tools to achieve excellent surface quality.

4. Carving and laser processing: For some high-precision applications, such as optical components or sapphire glass logos, carving and laser processing can create patterns and details.

5. Drilling: Drilling sapphire requires the use of special drill bits to break through its hardness, which is common in jewelry and other applications.

6. Refraction: Sapphire lenses can refract and transmit light, making them suitable for optical and laser applications.

Sapphire is an excellent multifunctional material with high temperature resistance, good thermal conductivity, high hardness, infrared transmittance, and good chemical stability. It stands out for its high hardness and transparency and is widely used in various fields, including optical lenses, laser systems, dials, and scientific research equipment. Therefore, sapphire lens processing requires highly specialized technology and precision equipment, and professional processing factories can usually provide high-quality customized processing services.

Tel

Mobile phone

Customer service

TOP