Time:2023-11-10

Sapphire is a general term for corundum gemstones of colors other than ruby, which can be pink, yellow, green, white, or even multiple colors for the same gemstone. Blue sapphire is caused by a small amount of titanium (Ti) and iron (Fe) impurities mixed in colorless transparent corundum. The sapphire watch mirror installed on watches now is actually made of aluminum oxide, which removes impurities such as iron oxide and titanium oxide. From a chemical perspective, synthetic sapphire is no different from natural sapphire. Since no other elements have been added, it is colorless and transparent, without any "blue" color.

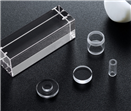

Mirror refers to the transparent lens on the surface of a watch, used to protect the dial. The watch is equipped with a double-sided anti reflective sapphire mirror, which not only ensures durability but also readability. The main reason for the high cost of sapphire crystal mirrors is the high production cost. Aluminum oxide is made from pure alumina at high temperatures and can be used to produce raw synthetic sapphires. Due to its high hardness, it needs to be cut into a disc using special diamond tools and then polished into a mirror.

The production of synthetic sapphire requires precise technology and production methods, and the process is complex. Synthetic sapphire is made of alumina, mixed with oxygen and hydrogen to achieve a melting point of 2050 ° C. It takes about 15 hours to form a "corundum" shaped rod (crystalline aluminum), which is then fired again at a high temperature of 1800 ° C to ensure the stability of the material. Next, use a diamond polishing blade to cut the "corundum", grind the crystal into thin sheets with a diameter not exceeding 0.02 millimeters, then perform mechanical processing, and finally polish the surface to the required standard thickness. After high and low surface grinding, curved or semi-circular crystal surfaces are produced. After chamfering, it is necessary to ensure that the sapphire watch mirror can fit tightly with the case, and both sides should be chemically polished. Then it is sent to the furnace in the sterile laboratory (white room) for anti reflection treatment through high-precision vacuum evaporation process.

Some watch enthusiasts may notice scratches on the sapphire watch mirror during use, most of which are caused by scratches on the mirror coating. Coating can reduce mirror reflection, increase transmittance, and correct color deviation. Adding a coating on the watch mirror is to reduce this reflection and improve the readability of the watch. The coating is composed of magnesium fluoride, which is easily scratched and cannot be repaired.

Tel

Mobile phone

Customer service

TOP