Time:2023-10-27

Sapphire substrates are suitable for replacing glass substrates when optical transmission is required in the ultraviolet (over 200 nanometers) or infrared (below 5 micrometers) range. Low temperature optical measurements will also benefit from the high thermal conductivity of sapphire window plates, which can be used in high-temperature environments up to 2300K.

1. Product specifications

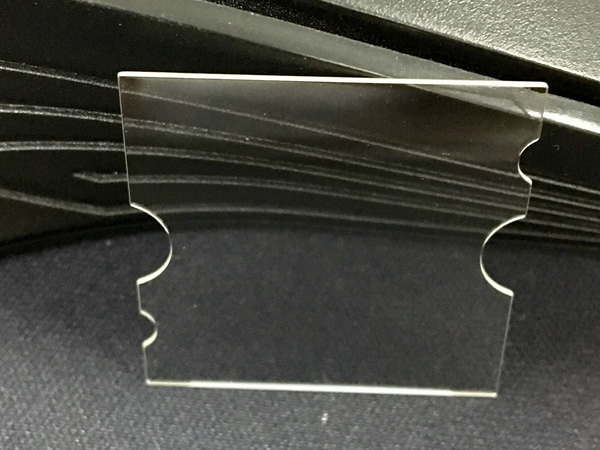

Below are three types of sapphire substrates with different surface treatments. The "standard" sapphire substrate has been polished to a 60/40 scratch surface quality, with an RMS roughness of approximately 0.3nm, suitable for most applications (including spectroscopy or thin film deposition). In contrast, the "ultra smooth" sapphire substrate has been polished to a scratch surface quality of 10/5, with an RMS roughness of approximately 0.1nm, making it suitable for applications involving atomic force microscopy, 2D materials, or any application where surface quality is crucial. Sapphire with a "rough" surface finish (although still smoother than most glass substrates) has a scratch rate of over 80/50 and a slightly higher RMS roughness of approximately 0.7 nanometers. If you don't have to worry about a small amount of optical scattering, these substrates are ideal choices.

2. Chemical properties

Sapphire is the crystal form of aluminum oxide (Al2O3), which is composed of Al3 cations and O2 anions arranged in a hexagonal lattice. It has chemical resistance to acids and bases (including hydrofluoric acid).

3. Mechanical performance

Sapphire has a particularly high hardness of 9, second only to diamond (10). By comparison, the hardness of glass is about 5.5. This makes it scratch resistant.

4. Optical characteristics

Sapphire is birefringent, which means its refractive index depends on the direction and polarization of light propagation in the crystal. Although birefringence has applications in various optical components, it is usually not popular in substrates used for optical measurements. To overcome this problem, the sapphire window plate is cut along the C plane, eliminating polarization dependent birefringence of normal incident light. Sapphire has a refractive index of approximately 1.76 in the visible spectrum and is transparent to light wavelengths between 200 nanometers and 5 micrometers, making it a preferred choice for ultraviolet and near-infrared/mid infrared applications. Sapphire has a lower transmittance in the wavelength range of 350nm-1000nm due to its higher actual refractive index (n), resulting in greater reflection of incident light at the air substrate interface.

5. Thermal performance

Sapphire has a high thermal conductivity of approximately 40W/m.K at room temperature, which is almost 50 times that of glass and twice that of stainless steel. As the temperature decreases, the value increases to about 10000 W/m.K. This makes sapphire suitable for low-temperature optical measurement, which requires thermal equilibrium between the sample and the thermostat, and also suitable for high-temperature environments of 2300K. The sapphire substrate has been polished to achieve optical quality, and its RMS roughness is significantly lower than that of the glass substrate.

Sapphire window panels have high hardness and scratch resistance, which are two important factors determining the quality of display screens and camera lenses. Mohs is usually used to indicate the hardness of an object, for example, the hardness of mica is 1 Mohs, the hardness of diamond is 10 Mohs, the hardness of glass is 5.5-7 Mohs, and the hardness of sapphire reaches 9 Mohs, which means its hardness is close to that of diamond.

Tel

Mobile phone

Customer service

TOP