Time:2024-06-07

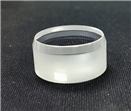

Sapphire glass is a material with excellent electrical insulation, transparency, good thermal conductivity, and high rigidity, which is widely used in many fields. Due to its excellent physical and chemical properties, it is considered an ideal substrate material for growing compound semiconductors such as III-V or II-VI compounds.

Sapphire is used as a substrate material to support chip manufacturing and integration in applications such as LED, microelectronic circuits, and ultra high speed integrated circuits. Due to its high rigidity and good thermal conductivity, sapphire can maintain stability in high temperature and high humidity environments, making it suitable for applications in various harsh environments.

When manufacturing sapphire glass, precision cutting and polishing are required to obtain a smooth mirror surface. This process requires placing the sapphire on a slicer and using special cutting tools to slice it into thin slices. After cutting is completed, the chip cutting damage layer can be removed to improve the flatness of the substrate and further optimize performance.

During the manufacturing process, it is also necessary to check the structural matching between the substrate and the epitaxial film to ensure a tight connection between them. This can be achieved by using equipment such as X-ray diffraction to measure the angle and orientation difference between the substrate and the epitaxial film.

After manufacturing, polishing and cleaning are also required to remove surface roughness and contaminants, ensuring high cleanliness and no metal contamination. These treatment steps can ensure the surface quality and performance of sapphire.

Sapphire glass, as an excellent substrate material, has been widely used in fields such as LED, microelectronic circuits, and ultra high speed integrated circuits. During the manufacturing process, precise cutting and polishing processes are required, as well as checking the structural matching between the substrate and epitaxial film. After manufacturing, cleaning and polishing processes are required to ensure surface quality and performance.

Tel

Mobile phone

Customer service

TOP