Time:2024-05-24

Sapphire glass has become a widely used synthetic single crystal material due to its superior mechanical, thermal, optical, and chemical properties, with good wear resistance and transparency. With the continuous development of technology, sapphire has also appeared in more high-end fields, widely used in the manufacturing of GaN epitaxial wafers, SOS microelectronic circuits, epitaxial wafers of other materials, optical components, etc. These application fields require high surface accuracy and smoothness of sapphire, thus requiring strict surface treatment.

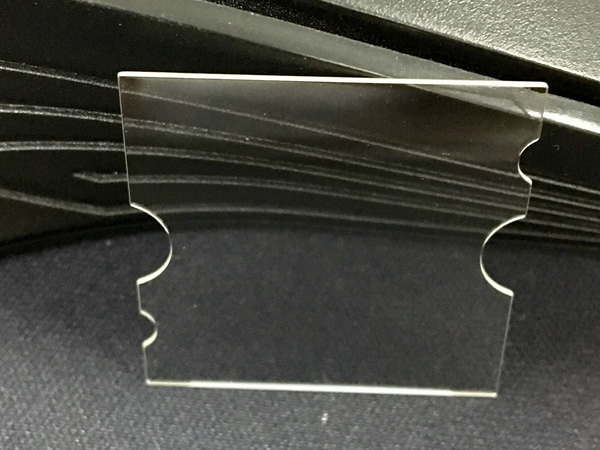

Sapphire needs to undergo processes such as squaring, cutting, grinding, polishing, and cleaning before use, which can reduce the surface roughness of sapphire workpieces and improve surface accuracy. Among them, grinding can be divided into rough grinding and fine grinding. At present, the precision grinding process mainly uses boron carbide powder (with a basic particle size of 3.5~5um) as the abrasive. In the rough grinding process, boron carbide micro powder (with a basic particle size of 3.5~5um) is mainly used as abrasive to perform preliminary grinding on sapphire glass to reduce surface roughness. After rough grinding, the surface of sapphire is relatively smooth, but there are still some obvious defects and unevenness.

In order to further improve the surface accuracy and smoothness of sapphire materials, precision grinding is required. During the grinding process, fine boron carbide powder (with a basic particle size of 0.5-1um) is used as the abrasive to finely grind the sapphire material. The extremely fine particle size of this abrasive can better remove small surface defects and unevenness. After precision grinding treatment, the surface accuracy of sapphire material is further improved, and the surface smoothness is also significantly enhanced. Meanwhile, precision grinding can also improve the hardness and wear resistance of sapphire materials to a corresponding extent. These characteristics enable sapphire to be more widely used in high-end applications, enhancing its market competitiveness.

Sapphire glass, as a widely used synthetic single crystal material, has superior mechanical, thermal, optical, and chemical properties, and is also widely used in high-end applications. To meet the requirements of these application areas, strict surface treatment processes are required, including edge grinding, cutting, grinding, polishing, and cleaning. Among them, precision grinding is one of the key steps in surface treatment, which can improve the surface accuracy and smoothness of sapphire workpieces, thereby enhancing their market competitiveness.

Tel

Mobile phone

Customer service

TOP