Time:2024-04-26

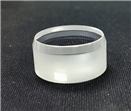

Sapphire lensesGenerally refers to synthetic sapphire, which, like tungsten titanium alloy and high-tech ceramics, is a wear-resistant material. Although these materials are wear-resistant, they cannot withstand strong impacts. Sapphire and corundum have similar compositions and a hardness of 9. Various colors can be produced by adding various chemical elements. The commonly used ones are colorless, harder than ordinary glass, and relatively expensive. In addition to high hardness, it also has excellent electrical and dielectric properties, as well as chemical corrosion resistance, high temperature resistance, good thermal conductivity, high hardness, infrared transmission, and good chemical stability. Therefore, in some industrial fields, many instruments and meters often use it instead of other optical materials to make optical components, infrared transparent optical windows, etc.

Sapphire's hardness is second only to diamond. By purifying its elements and applying them to some transparent glass panels, better hardness performance can be obtained than traditional chemically strengthened glass. According to the above information, the hardness value of sapphire is 9, while the hardness value of glass is 5. The fracture toughness value of the former is 2.3 MPavm, which is almost 3 to 4 times that of ordinary glass. In the mobile phone industry, sapphire lenses can improve the scratch resistance of mobile phone screens. The production process of sapphire is complex, with longer production time and much higher temperature requirements than ordinary glass. Due to its high hardness, the production process is also relatively complex. If there are problems in the furnace, the cost of post cutting may increase exponentially.

Sapphire lenses have good thermal performance, excellent electrical and dielectric properties, and are resistant to chemical corrosion. High temperature resistance, good thermal conductivity, high hardness, transparency to infrared radiation, and good chemical stability are often used to replace other optical materials in the production of optical components and infrared optical windows. Due to its high hardness and brittle material, edge cracking and fragmentation are prone to occur during the processing. Special precision engraving machines are usually used to process glass parts, which can effectively reduce costs and achieve high-precision processing.

Tel

Mobile phone

Customer service

TOP