Time:2024-04-19

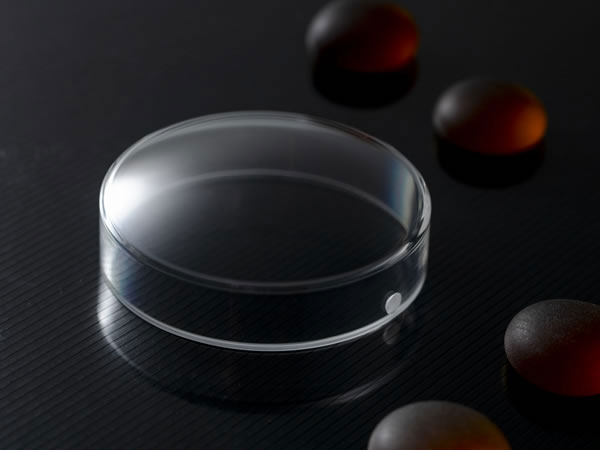

Sapphire high and low temperature resistant glass refers to non red alumina, which has characteristics such as high sound speed, high temperature resistance, corrosion resistance, high hardness, high transmittance, and high melting point. It is a difficult to process material and is often used as a material for photovoltaic modules. It is an important foundational material for modern industry, especially microelectronics and optoelectronics. The industrial production of sapphire is to use alumina to produce original synthetic sapphire from pure alumina under high temperature conditions. After multiple processes, it is cut into discs using diamond tools and then polished into mirror surfaces. Due to the high cost of processing tools and the high consumption of mesh, the production cost of sapphire mirror is relatively high.

The process of synthesizing sapphire is as follows: the raw material is decomposed into clean crystal components at a high temperature of 1200 ℃. After decomposition, there is pure white crystal raw material. Then, the required crystal strips are fired at a temperature of 2050 ° C. After obtaining the crystal strip, manually screen the fired crystal strip again. After screening, each crystal bar must be clean and flawless. Because sapphire high and low temperature resistant glass requires mirror treatment, this material is cut into crystal strips, and then the crystal glass pieces are sorted out. After cutting, use a grinder to grind the surface at low speed. This work requires at least 4 cycles to achieve a bright and transparent mirror effect. After processing, it is sent to a clean room for optical processing, and special optical media is coated on both sides of the mirror surface at a high temperature of 280% C.

The growth and slicing process of sapphire heat-resistant glass is very similar to the production and slicing of single crystal silicon, using diamond sand wire cutting, which can be used for sapphire slicing. The handle is easy to operate and the wire cutting is smooth, which improves the processing efficiency of the slicer. The outer side of the guide wheel is equipped with an automatic detection diamond wire breakage protection device to ensure the safety of the entire slicing process. The finished product is smooth and of high quality, thereby reducing production costs and increasing economic benefits.

Tel

Mobile phone

Customer service

TOP